UTSM Aero-Body

Project Overview

The Universith of Toronto Supermileage Design Team (UTSM) is involved in the fabriation of a high-efficiency vehicle to compete at the Shell Eco-Marathon. The team fully designs and builds two different vehicles: an urban conept vehicle that meets street safety regulations, and a prototype vehilce that maximizes efficiency through aerodynamics.

My Involvment

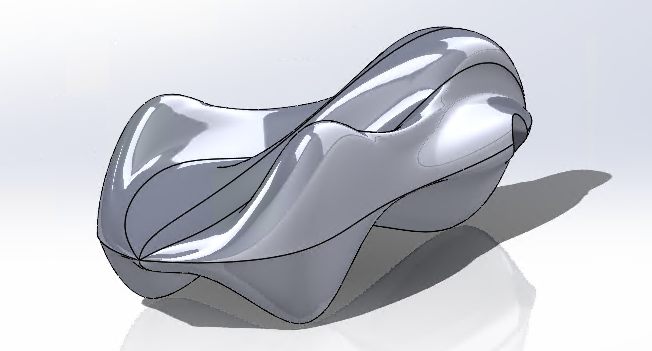

As part of the Aero-Structural team on the prototype vehicle, my projects primarily focus on manufacturing and design of the car's aerobody. One of my major projects involved the design and simulation of an aerobody. This involved CAD modelling the structure and basic geometry of the car, including the definiation of curves and features that would optimzie air flow around the vehicle. This was then simulated using ANSYS Fluent to determine the draf coefficient and efficiency of the vehicle. The results of the simulation showed a reasonable drag coefficient of 0.09, but could be iterated on to improve the its performance and feasibility for manufacture.

Another major componeont of the team I'm involved in is the manufacture of the aerobody. This involves performing carbon fibre layups to yield the general structure of the car. After layups the team sands the car to achieve a smooth aerodynamic finish before painting. This process requires attention to detail and precision to ensure the car meets the required specifications.

My Career Considerations

This experience has been rewarding for me as the team runs similar to a small business in that your work directly impacts the success of the team, and everyone works very closely together under a tight schedule to achieve the team's goals. From an engineering perspective, my involvement on the team has sparked interest into aerodynamic modelling and simulation. Design vehicles for speed is fun, but fuel efficiency and sustainability is where the world is going. For these reasons, I've considered the work I do at UTSM as leading to a potential career path in a similar industry.