Continuous Casting Research @ UofT

Project Overview

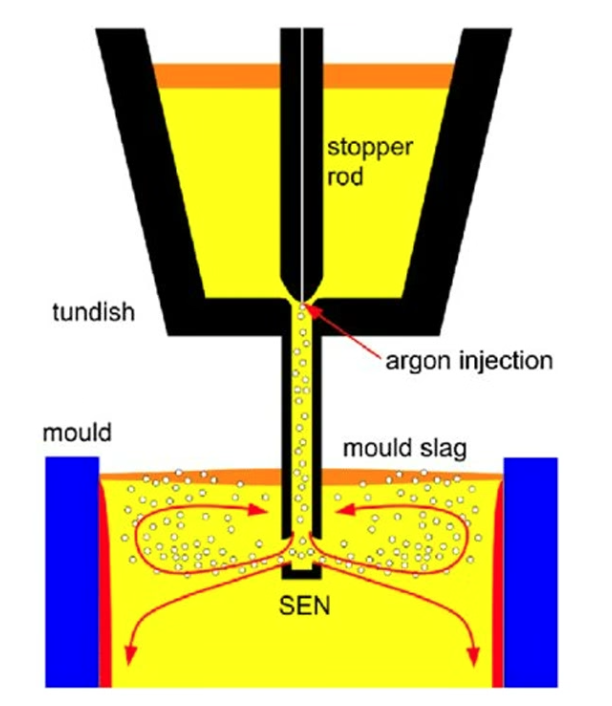

Continuous casting is a steelmaking process in which molten steel flows from a bathtub-like vessel, through a Submerged Entry Nozzle (SEN), and into a mould where it gradually cools and solidifies into steel slabs. Due to impurities in the steel, argon gas is injected into the mould to help capture these impurities and carry them upward, away from the solidifying metal.

The molten steel flow rate, the gas injection rate, and the geometry of the SEN all influence both the purity of the final steel and the efficiency of its production. To study how changes in these parameters affect this process, a full-scale water model is used, substituting water for molten steel and air for argon. By collecting detailed flow-field data from this model, accurate conclusions can be drawn that guide the optimization of continuous steel casting.

My Involvment

I was hired as a research intern in May 2025 to conduct experiments and process data in relation to the continuous casting model at UofT. Under the guidance of Prof. Dr. Markus Bussman, Prof Dr. Ali Asgarian, and Dr. Joydeep Sengupta, I operated the water model and ran data collection of the flowfield using a Particle Image Velocimetry (PIV) system and anemometers. The purpose of the data collection was to train a digital twin for the mould. With two different data collection methods, it was necessary to characterize the measurement mismatch between the two sources. I developed a processing procedure that helps characterize this mismatch and provides valuable insight into the operation of the mould. I additionally processed bubble images through ImageJ and various ML models, with the intention of determining bubble count and size distribution throughout the mould. I presented my findings at ArcelorMittal's Innovation Seminar and the University of Toronto's UnERD Research Day. I'm currently in the midst of coauthoring a research paper that further details my discoveries for academia.

Development of My Processing Procedure

Data in the mould is collected using two distinct methods. Particle Image Velocimetry (PIV) uses a laser to illuminate small particles that are injected into the mould. A high speed camera then takes images of these particles during mould operation, yielding flowfield data from 2D areas of interest. These images are transformed using PIV software into vector fields, which can be exported and turned into contour plots using custom-built Python scripts. In addition to PIV data, sensors are used to collect flow data from single points within the mould. Anemometers collect horizontal flow data, and Ultrasonic Level Sensors measure height fluctuations, capturing the standing wave that forms along the mould's surface. PIV data can be collected at a higher frequency but for a shorter amount of time (around 10 seconds) due to the limitations of the equipment. The sensors however can collect data for longer periods of time, typically around 5 minutes, at a lower frequency.

I noticed when running these experiments and processing the data that the time-averaged velocity at points within the mould was distinctly different when measured with PIV versus with the anemometers. This mismatch was noticed across all different experimental parameters and was not uniform in magnitude. However, the majority of the time it was the anemometers that recorded a lower velocity. To address this, my lab supervisor and I placed a camera close to one of the anemometers during mould operation. We noticed that the bubbles used to model the gas injection in the mould were actually getting trapped in the anemometer blades, inhibiting their rotation and thus the measurement. To explore this further, I plotted the anemometer signal for the full 5 minutes of data recording. I noticed two significant features of the plot when I did this. First, there were mutliple lcoations on the plot where the signal would flat line. This meant that the anemometer was recording the lowest velocity its capable off, effecitvely meaning it had stopped rotating. In continuous flow, this would only be possible if the anemometer was being obstructed. Second, I noticed a dominant oscillation in the signal with a frequency ranging from 30 to 50 seconds. This was significant as PIV data could only be collected for 10 seconds, meaning it was completely depended on luck whether the PIV data was collected during a high or low velocity period.

To address both of these problems, I developed an effective processing procedure that would more meaningfully compare these data sources. Firstly, all 'problem points' in the signal would be filtered out. This included any point that measured the lowest possible velocity or was within a certain threshold of a lowest velocity point. This would reduce the effect of 'bubble entrapment' effecting the signal. Secondly, I wrote a script that would incrementally step the PIV signal through the anemometer signal, taking the average difference between aligned data points to determine the interval of best match. This way, the PIV data would effectively be 'placed' into the accurate location where it corresponded with the anemometer signal. After applying these two steps, the mismatch between the measurements significantly reduced. This lead to much more accurate flowfield characterization within the mould, and future understanding of how the mould operates.

Takeaways - My Career Considerations

Overall, the work I did at UofT under my supervisors was immensely rewarding. I enjoyed coming to the lab to run experiements and process data, all while feeling like I was on the cutting edge of flowfield measurement, and doing meaningful work towards the goal of a digital twin for continuous casting optimization. I found I enjoyed that everyday came with it a new challenge to solve and something new to learn. I also particularly enjoyed presenting my work at the two opportunities I had, and providing weekly update meetings to my supervisors.

As a result of this career, I've been considering careers that relate to research. Whether that be working at an R&D center for a major company, such as ArcelorMittal with continous casting, or working in a more academic setting, pursuing a Master's or PhD degree. Research is a unique field and very distinct from the other career paths I've been considering. However, the beauty of research is that it can be applied to almost any field, and customized to suit the interest's of the researcher. For these reasons, it is an exciting career path that I'm eager to explore further.