Robotic Arm for Cinematography

Project Overview

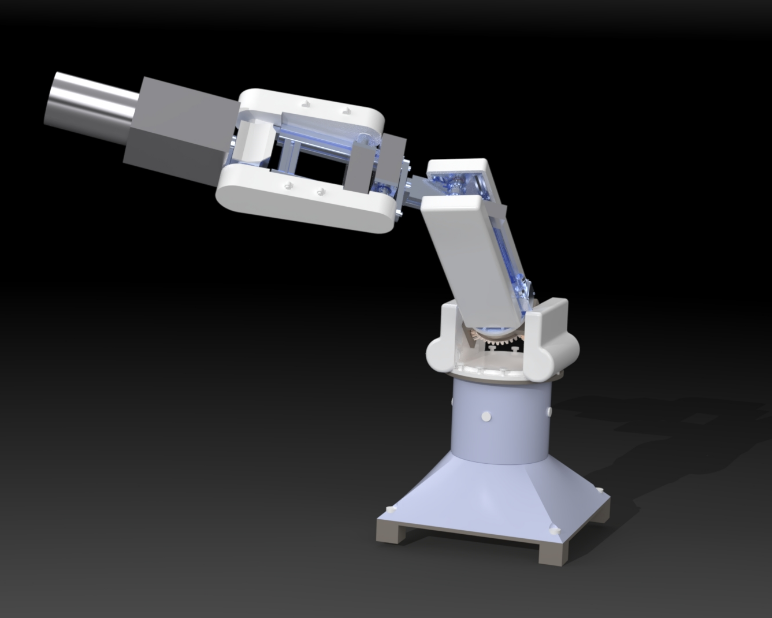

In my second year of Mechanical Engineering, a group of peers and I designed a Robotic Arm for Cinematography. as part of our MIE243: Mechanical Design course. As a group, we set about this process by identifying the problem from an engineering perspective and defined a set of technical specifications that would help us in scoping a solution. The design was meant to cater to content creators and small indie filmmakers, who want to have access to an entry-level robotic arm for their projects. As we progressed through the design process, we performed idea generation and employed our knowledge of mechanical mechanisms to develop a set of candidate designs. These candidates ranged from robots with scissor-lift joints, expansive pulley systems and everything in between. We eventually settled on a unique mix of mechanism that would power a simple 6 DOF robot in a fully defined space. A major focus of this project was designing our robot arm in Computer Aided Design (CAD) software. By the end of the semester, we presented a fully formed robot arm with an accompanying project document detailing the design specifications, methodology behind our design, and fully defined drawings of each component in the design.

My Contribution - Methodology

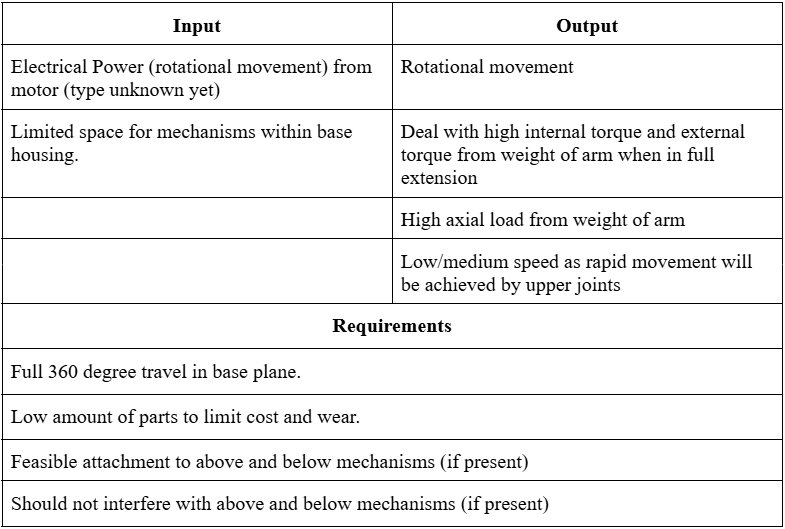

My contribution to this project was the design and evaluation of the robot's base. This joint had to achieve 1 DOF rotational motion in the horizontal plane, and be designed to sustain significant axial forces and torques from the movement of the arm it supported. Additionally, it was important to consider reducing the cost of the design, and thus a constraint on the design was trying to use as many standardized parts as possible.

In planning the development of the robot's base, I scoped out the requirements for the base, as well as the mechanism's inputs and outputs. This outline, known as the "Black Box Method", was fundamental in helping me scoping out the aspects of the design and efficiently selected a set of potential mechanisms.

From this point, I was able to reference the table to define a set of mechanisms that could be employed in the design. These were primarily mechanisms that I had become familiar with over the course of the semester, and ranged from belt and chains to bevel gears. As I considered these options, I wanted to keep in mind some critical requirements from the Black Box. Firstly, the design had to be able to sustain high torques, and achieve high torque outputs. Seeing as I would have limited space for the size of the motor, I knew I would need to employ a gearbox that could achieve a high reduction ratio for increased torque. Additionally, it would be most suitable in the design to have the motor located directly under the mechanism, which would be most ideal for high external torques from the weight of the arm. As such, to suit high torque output with collinear input and output, I selected a planetary gearbox as the most suitable mechanism.

My Design

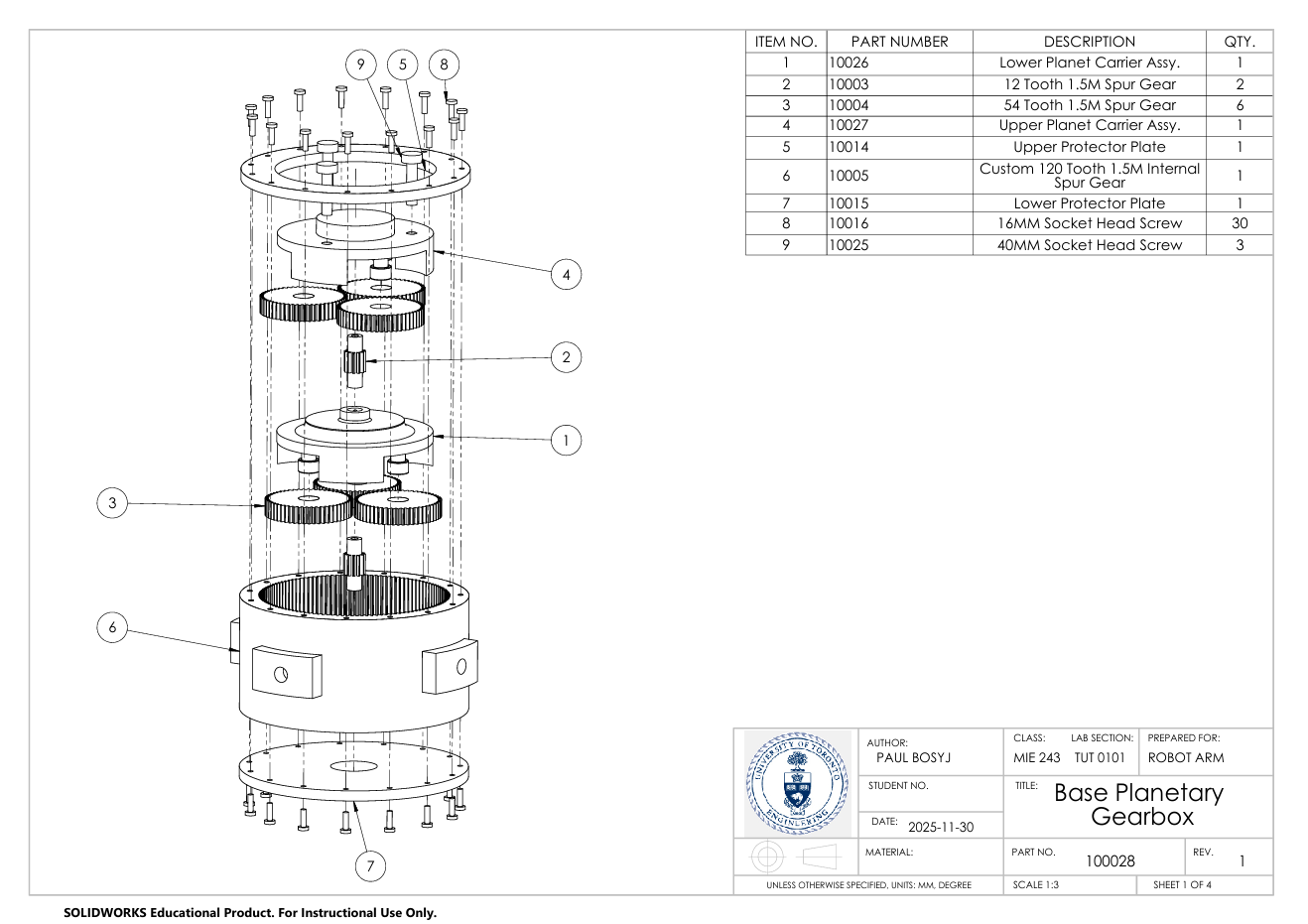

To adhere with the necessary torque requirements of 1300 lb-in of force created at the base, a DC servomotor with a continuous torque output of 21.2 lb-in is paired with a two stage planetary gearbox with a gear reduction of 121:1. The design uses spur gears, which are cheaper than helical gears with the tradeoff of being louder during operation. To account for this, a sound barrier was designed between the external ring gear of the gearbox and the casing. This barrier could be filled with a mechanical dampening material, such as a viscoelastic polymer, or left open with air. Adequate testing of this solution could really only be performed with a fabricated prototype. In addition to the sound barrier, the design had to include features for dust resistance and mechanism containment. This was both for the longevity of the design, as well as the safety requirements that our group set out to achieve at the start of our process. As such, gaskets and casings were included on the design, with the necessary tolerances and attachment methods to serve their purpose. Lastly, I include a rigid attachment method between my design and the upper joint, ensuring that adequate torque could be transferred across the linkage and the joints could work together feasibly.

What I Learned - My Career Connection

Throughout the development of our robot, I learned a lot about mechanical design, mechanism integration and various DFX considerations. This was a valuable experience as it helped me understand more about the design work that professional engineers do, and the justification and reasoning that goes behind specific design decisions. My exposure to thinking about mechanical components and their usefulness in certain designs inspired me to think critically about mechanisms present in everyday life. Understanding the significance of the design process, from problem definition, ideation and selection, to fully formed solution, has helped shape my perspective on a career in engineering design.

I want I truly enjoyed from this experience was working directly on ideating design compoents that I could later visualize and model on CAD software. I enjoyed the start-to-end experience of seeing the entire process, while still getting the opportunity to work hands-on on the design, such as running calculations and adding components. I can see the reward and value in a career like this, especially if the design relates to something with a greater impact in its environment, such as design prosethic joints, or optimizing mechanical components used in construction or transportation.

Teamwork

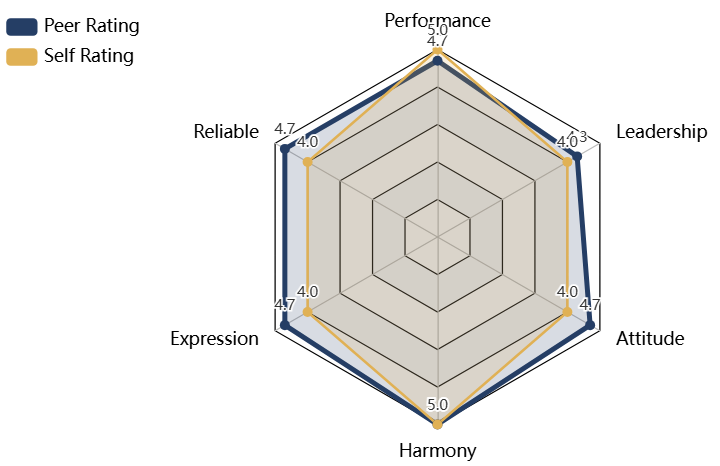

Throughout this project I had the opportunity to work as part of a design team with my peers. As a result, I learned valuable lessons in task delegation, project management, and how to be effective as a leader and communicator.

In terms of project management, my team established a weekly time slot for team meetings. At these meetings we discussed what each of us had worked on and what was accomplished on the project from the previous week. We would have a work session during these meetings where we were able to spend time together figuring out specific components of our design, and then we assigned and delegated tasks for the following week. We ensured that meeting notes were taken and discussions that revolved around critical decisions and directions for our design were effectively thought out and reasoned.

A major bonus to our teamworking style was our communication and organization. We kept each other informed of what we were doing, let each other know if we were struggling on a specific task, and held each other accountable. This was critical as we were all busy students who were trying to balance other courses and jobs while working on this project. To maintain organization, we integrated our meetings and work periods into our schedules, helping us keep on track and stay accountable on tasks that required attention. This also allowed us to block off times during the week when we could discuss progress outside of meetings if there were specific deliverables that needed our attention.

At the midpoint of the project, we had an opportunity to provide feedback to each other through a peer evaluation. This was a great chance to reflect on how we were working as a team, and gain insight on what we were each doing individually that our team members had observed. From this exercise, I realized that I was strong in my leadership and communication skills as my team members had indicated, but I could improve on my time management and task delegation. As I continue to grow as an engineer, understanding how to effectively work n a team is critical. I appreciate the opportunity to get this feedback as I could understand where I could imporve.